Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

FGD Gypsum Production Line

Description

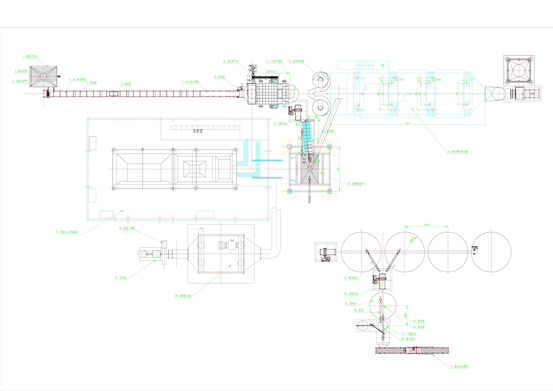

Flue-gas desulphurization (FGD) is a set of technologies used to remove sulfur dioxide (SO2) from exhaust flue gases of fossil-fuel power plants and from the emissions of other sulfur oxide emitting processes. The FGD gypsum production line is composed of hot air furnace, preheating system, calcining system, dust collecting system, modifying system, conveying system, packing system and storage system.Technology of FGD Gypsum Production Line

The desulfurized gypsum equipment has adopted advanced technology in the whole system. Two-step calcining technology is adopted in FGD gypsum making machine. The first step is pre-drying, and the second step is calcining in the furnace.Application of Gypsum Powder Production Line

After the FGD is treated with our production line, the FGD gypsum can be used as construction gypsum and agricultural gypsum.Working Process of FGD Gypsum Production Line

The basic process of making gypsum powder is: FGD raw material —— preheating —— calcining —— dust collecting —— pin mill modifying —— silo—— packing machineTypical Process of Gypsum Powder Production Line

Capacity of FGD Gypsum Production Line

| Capacity/year | Capacity/hour | FGD Raw Material Consumption | Calciner Size |

| 30,000 tons/year | 4.2 tons/hour | 45,000 tons/year | 4.5 × 1.2 × 1.4 m |

| 50,000 tons/year | 6.9 tons/hour | 75,000 tons/year | 4.5 × 1.4 × 1.6 m |

| 60,000 tons/year | 8.3 tons/hour | 90,000 tons/year | 4.5 × 1.6 × 1.8 m |

| 100,000 tons/year | 13.88 tons/hour | 150,000 tons/year | 4.5 × 2.0 × 2.2 m |

| 150,000 tons/year | 20.83 tons/hour | 225,000 tons/year | 4.5 × 2.2 × 2.4 m |

| 200,000 tons/year | 27.77 tons/hour | 300,000 tons/year | 4.5 × 2.4 × 2.6 m |

Features of FGD Gypsum Production Line

1. Both the preheating system and the calcining system use the same energy source: hot air furnace. This makes the production line more energy-saving and less investment cost.2. The pin mill or ball mill is arranged after calcining. It modifies the FGD gypsum, and makes the gypsum powder production line have stable performance.

3. Horizontal dust collecting system improves the filtering result.

4. Hot air is recycled. More energy is saved and the production cost is lower.

5. DCS control system is adopted in the production line. It supplies more automatic control level, much stable running performance, and more reliable quality.

Installation of FGD Gypsum Production Line and Training to Operators

1. Engineers and technicians from our company will be dispatched to the installation site to give instruction in the installation and commissioning work.2. The buyer shall supply welding workers and fitters to cooperate in the work of installation and commissioning.

3. During the installation and commissioning, the buyer’s operators will be trained in respect of operation, trouble-shooting and maintenance by the technicians and engineers.