Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

Gypsum Mixing Machine

Description

The gypsum mixing machine (plaster mixer) is composed of weighing silos, conveyors, mixer, packing silo, packing machine.Plaster, stucco or render is a building material used for coating walls and ceilings. It is manufactured as gypsum which is mixed with water to form a paste when used.

The reaction with water liberates heat through crystallization and the hydrated plaster. Plaster can be relatively easily worked with metal tools or even sandpaper. These characteristics make plaster suitable for a finishing, rather than a load-bearing material.

The gypsum is the main raw material of the plaster. The additives include citric acid, starch ether, glue powder and cellulose. They are mixed in the mixer at a certain ratio. After mixed with the four additives, the gypsum is much stronger, has a longer setting time, and easy to plaster on the wall or ceiling.

Capacity of Plaster Mixer

Volume of the mixer is 6 tons.Capacity of the production line is 3 tons per hour.

Working Process of Gypsum Mixing Machine

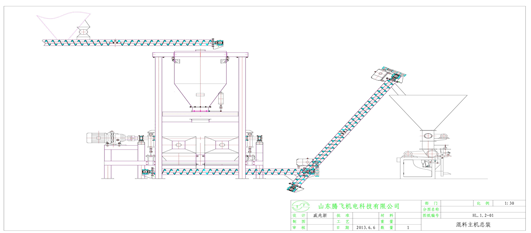

The basic process of mixing is: gypsum weighing + additives weighing ——mixing —— conveying —— silo —— packingFeatures of Plaster Mixer

Accurate weighingEffective mixing result (as good as 0.1%)

Fully automatic

High dust collecting effect

Typical Process of Gypsum Mixing Machine

Installation of Gypsum Mixing Machine and Training to Operators

1. Engineers and technicians from our company will be dispatched to the installation site to give instruction in the installation and commissioning work.2. The buyer shall supply welding workers and fitters to cooperate in the work of installation and commissioning.

3. During the installation and commissioning, the buyer’s operators will be trained in respect of operation, trouble-shooting and maintenance by the technicians and engineers.

Related Products

-

-

Gypsum Board Production Line

The gypsum board production line (plasterboard machine) is composed of raw material batching system, mixer, board forming station, board setting line, cut-off knife, transfer table, dryer, booking machine, trimming machine and stacker. ...

-

-

Gypsum Powder Production Line

The raw material of gypsum powder can be from natural gypsum rock, phosphogypsum, FGD (flue-gas desulfurization). The gypsum powder production line (gypsum plaster machine) is composed of crushing system, grinding system, calcining system, energy supply system, conveying system, packing system and storage system. ...

-

-

Gypsum Block Production Line

Gypsum block is a massive lightweight building material for building fire-resistant interior walls, partition walls, cavity walls, skin walls and pillar casing indoors. Gypsum block is composed of solid gypsum plaster, water and additives (like vegetable, wood fiber). ...

-

-

Gypsum Board PVC Ceiling Tile Machine

Gypsum board PVC ceiling tile machine is based on the paper faced gypsum board with thickness of 6 mm to 8 mm, spread with special glue on both side, then laminated PVC film and PET foil. After laminating, the board is cut into smaller size: 60 × 60 mm. The plasterboard PVC laminating production line is composed of board loading machine, glue spreader, laminating machine, press, lengthwise cutter, widthwise cutter, side taping machine, stacker, shrinking and packing machine. ...